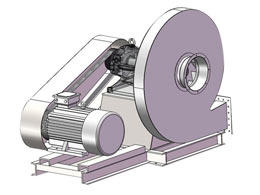

MHHT-350F Heavy Duty Centrifugal Fans

- Impeller diameter: 1800-3300mm

- Speed of main shaft: ≤1450rpm

- Pressure range: 2171-12259Pa

- Flow range: 15189-703455m3/h

We're here to help: Easy ways to get the answers you need.

Overview

MHHT-350F high pressure heavy centrifugal fan, is suitable for conveying incombustible gas at normal temperature or high temperature and Particle materials / Powder materials / Fragment materials / Fiber materials, outputting air flow slightly superior to MHHT-200 heavy centrifugal fan. It is mostly applied to sintering system, large dust collectors, large industrial rotary kilns / calcining kiln conveying materials / blowing air / inducing air, large boiler induced draft, industrial waste gas desulfurization or denitration and other industrial applications.

Features

1. Customizing design according to customer’s performance requirements, and optimizing by CFD technology, energy consumption lower than same fans.

2. Blades angle going through optimizing design, higher wear resistant, longer service life.

3. Can flexibly adjust fan’s volume and pressure in running by air damper. Can also adjust fan’s pressure and volume by changing the fan speed via matching variable frequency motor.

4. Fan is equipped with temperature and vibration sensors, easy to install the fan running monitoring device

5. Adopting high quality carbon steel manufacturing, or stainless steel and other metal materials according to customers’ requirements.

6. The welding line of impeller and main shaft passed ultrasonic flaw detection, ensuring no defect of welding and materials, guarantee strength.

7. Cooling method of bearing, choosing low cost water cooling method or good heat dispersion oil cooling method according to gas temperature and running condition. Or installing BOX COOL for very high temperature medium condition to protect fan system operation reliable completely.

8. Large parts disassembled transport, make the most of the parts can be loaded into the container for transportation, for you save freight cost

9. Installation numbers for every part, can smoothly complete system trial assembly under the direction of manual.

10. Provide on site arrangement service.

MHHT-350F high pressure heavy centrifugal fan, is suitable for conveying incombustible gas at normal temperature or high temperature and Particle materials / Powder materials / Fragment materials / Fiber materials, outputting air flow slightly superior to MHHT-200 heavy centrifugal fan. It is mostly applied to sintering system, large dust collectors, large industrial rotary kilns / calcining kiln conveying materials / blowing air / inducing air, large boiler induced draft, industrial waste gas desulfurization or denitration and other industrial applications.

Features

1. Customizing design according to customer’s performance requirements, and optimizing by CFD technology, energy consumption lower than same fans.

2. Blades angle going through optimizing design, higher wear resistant, longer service life.

3. Can flexibly adjust fan’s volume and pressure in running by air damper. Can also adjust fan’s pressure and volume by changing the fan speed via matching variable frequency motor.

4. Fan is equipped with temperature and vibration sensors, easy to install the fan running monitoring device

5. Adopting high quality carbon steel manufacturing, or stainless steel and other metal materials according to customers’ requirements.

6. The welding line of impeller and main shaft passed ultrasonic flaw detection, ensuring no defect of welding and materials, guarantee strength.

7. Cooling method of bearing, choosing low cost water cooling method or good heat dispersion oil cooling method according to gas temperature and running condition. Or installing BOX COOL for very high temperature medium condition to protect fan system operation reliable completely.

8. Large parts disassembled transport, make the most of the parts can be loaded into the container for transportation, for you save freight cost

9. Installation numbers for every part, can smoothly complete system trial assembly under the direction of manual.

10. Provide on site arrangement service.

>> INQUIRY

E-mail: hengtongblower@163.comTel: 0086-373-5467003(5467018)