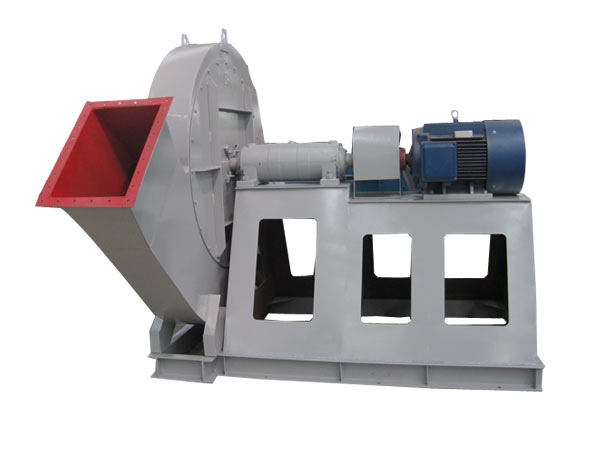

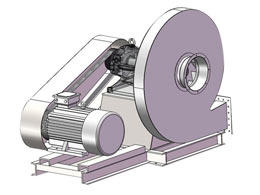

GHHT-135D Industrial Blowers and Fans

- Impeller diameter: 250-2000mm

- Speed of main shaft: ≤4000rpm

- Pressure range: 348-15425Pa

- Flow range: 273-81858m3/h

We're here to help: Easy ways to get the answers you need.

Overview

GHHT-135D fan is most commonly used in forced ventilation, fast dry, fast cooling and heat dissipation, cement production line of grate cooler cooling, Clinker cooler system, Circulating fluidized bed(CFB) system, air purification and industrial waste gas treatment, flue gas desulfurization, industrial boiler or incinerator blowing air/inducing air/primary air/secondary air, ventilating of large mill system, industrial waste heat recovery device, smelting furnace and foundry furnace, combustion of blast furnace, blast furnace coal injection, coal gas boosting and conveying or pressurization and decompression seal of industrial equipment, etc. The number of this type of fans is largest that is used in industrial field of HENGTONG BLOWER. they can output high gas pressure, and is suitable for conveying clean/combustible/corrosive/a little impurity gas at normal temperature, or lightweight powder/debris/short fiber materials.

Features

1. Can output higher discharge pressure, in the same time provide larger air flow volume, low noise. Can work stably under high temperature conditions

2. Cooling method of bearing, chooses low cost water cooling method or good heat dispersion oil cooling method according to gas temperature and running condition. Or install BOX COOL for very high temperature medium condition to protect fan system operation reliable completely.

3. The motor load can be automatically reduced when airflow resistance is increasing, to prevent motor from destroying.

4. Can satisfy different dust loading conditions from low dust loading to large dust loading, the surface hardness of impeller can reach to HRC60~70 after special processing, greatly extend impeller’s service life.

5. Bearing housing reserves installation place for temperature and vibration sensors, can install easily of fan running monitoring device.

6. The welding line of impeller and main shaft passed ultrasonic flaw detection, ensuring no defect of welding and materials, guarantee strength.

7. Running test and vibration value test for fans is done after finishing manufacturing, ensuring reliable running

8. In the case of using system base, it is very easy for installation, no need professional direction.

9. Various optional components for your selection.

GHHT-135D fan is most commonly used in forced ventilation, fast dry, fast cooling and heat dissipation, cement production line of grate cooler cooling, Clinker cooler system, Circulating fluidized bed(CFB) system, air purification and industrial waste gas treatment, flue gas desulfurization, industrial boiler or incinerator blowing air/inducing air/primary air/secondary air, ventilating of large mill system, industrial waste heat recovery device, smelting furnace and foundry furnace, combustion of blast furnace, blast furnace coal injection, coal gas boosting and conveying or pressurization and decompression seal of industrial equipment, etc. The number of this type of fans is largest that is used in industrial field of HENGTONG BLOWER. they can output high gas pressure, and is suitable for conveying clean/combustible/corrosive/a little impurity gas at normal temperature, or lightweight powder/debris/short fiber materials.

Features

1. Can output higher discharge pressure, in the same time provide larger air flow volume, low noise. Can work stably under high temperature conditions

2. Cooling method of bearing, chooses low cost water cooling method or good heat dispersion oil cooling method according to gas temperature and running condition. Or install BOX COOL for very high temperature medium condition to protect fan system operation reliable completely.

3. The motor load can be automatically reduced when airflow resistance is increasing, to prevent motor from destroying.

4. Can satisfy different dust loading conditions from low dust loading to large dust loading, the surface hardness of impeller can reach to HRC60~70 after special processing, greatly extend impeller’s service life.

5. Bearing housing reserves installation place for temperature and vibration sensors, can install easily of fan running monitoring device.

6. The welding line of impeller and main shaft passed ultrasonic flaw detection, ensuring no defect of welding and materials, guarantee strength.

7. Running test and vibration value test for fans is done after finishing manufacturing, ensuring reliable running

8. In the case of using system base, it is very easy for installation, no need professional direction.

9. Various optional components for your selection.

>> INQUIRY

E-mail: hengtongblower@163.comTel: 0086-373-5467003(5467018)