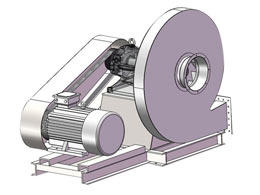

DFHT-288F Industrial Centrifugal Fans

- Impeller diameter: 1800-3300mm

- Speed of main shaft: ≤1450rpm

- Pressure range: 2171-12259Pa

- Flow range: 15189-703455m3/h

We're here to help: Easy ways to get the answers you need.

Overview

DFHT-288F heavy centrifugal fan, the enhanced type of excellent DFHT-288 high pressure heavy centrifugal fan. On the basis of constant pressure, DFHT-288’s suction/output flow rate doubled. It is usually used in conveying incombustible gas at normal temperature or high temperature and Particle material/ Powder material/ Fragment materials/Fiber materials. Its application is very broad, in large dust collector system, industrial waste gas desulfurization or denitration, large industrial boiler system, large industrial rotary kiln/ calcining kiln system, mineral powder sintering (sintering machine), large induced draft system and other industrial system.

Features

1. Can output higher discharge pressure, and working at high medium temperature condition, applicable to any industry condition which need to conveying high pressure & high temperature gas.

2. Can flexibly adjust fan’s volume and pressure in running by air damper. Can also adjust fan’s pressure and volume by changing the fan speed via matching variable frequency motor.

3. Regarding to material of impeller and main shaft, we will choose high strength carbon steel, low alloyed steel, high temperature resistant alloy steel, high temperature resistant high strength alloy steel according to different medium temperature and running speed, ensuring the impeller and main shaft keeping reliable strength in high temperature.

4. Can satisfy different dust loading conditions that low dust loading to a good deal dust loading, the surface hardness of impeller can reach to HRC60~70 after special processing, greatly extending impeller’s service life.

5. Bearing housing reserves installation place for temperature and vibration sensors, can install easily of fan running monitoring device.

6. Fitting tightly of parts, good sealing, ensuring no reducing of output pressure.

7. Impeller of annealing treatment, completely eliminating structure of internal stress when welding, ensuring impeller appearance won’t occur creepage and flaw.

8. The welding line of impeller and main shaft passed ultrasonic flaw detection, ensuring no defect of welding and materials, guarantee strength.

9. Impeller passed high standard dynamic balancing, ensuring stable running of fan.

10. Trial assembly after finishing production, ensuring no interference between components.

11. Adopt detachable design for fan system, greatly reducing the transportation cost.

12. Providing on-site guidance services.

DFHT-288F heavy centrifugal fan, the enhanced type of excellent DFHT-288 high pressure heavy centrifugal fan. On the basis of constant pressure, DFHT-288’s suction/output flow rate doubled. It is usually used in conveying incombustible gas at normal temperature or high temperature and Particle material/ Powder material/ Fragment materials/Fiber materials. Its application is very broad, in large dust collector system, industrial waste gas desulfurization or denitration, large industrial boiler system, large industrial rotary kiln/ calcining kiln system, mineral powder sintering (sintering machine), large induced draft system and other industrial system.

Features

1. Can output higher discharge pressure, and working at high medium temperature condition, applicable to any industry condition which need to conveying high pressure & high temperature gas.

2. Can flexibly adjust fan’s volume and pressure in running by air damper. Can also adjust fan’s pressure and volume by changing the fan speed via matching variable frequency motor.

3. Regarding to material of impeller and main shaft, we will choose high strength carbon steel, low alloyed steel, high temperature resistant alloy steel, high temperature resistant high strength alloy steel according to different medium temperature and running speed, ensuring the impeller and main shaft keeping reliable strength in high temperature.

4. Can satisfy different dust loading conditions that low dust loading to a good deal dust loading, the surface hardness of impeller can reach to HRC60~70 after special processing, greatly extending impeller’s service life.

5. Bearing housing reserves installation place for temperature and vibration sensors, can install easily of fan running monitoring device.

6. Fitting tightly of parts, good sealing, ensuring no reducing of output pressure.

7. Impeller of annealing treatment, completely eliminating structure of internal stress when welding, ensuring impeller appearance won’t occur creepage and flaw.

8. The welding line of impeller and main shaft passed ultrasonic flaw detection, ensuring no defect of welding and materials, guarantee strength.

9. Impeller passed high standard dynamic balancing, ensuring stable running of fan.

10. Trial assembly after finishing production, ensuring no interference between components.

11. Adopt detachable design for fan system, greatly reducing the transportation cost.

12. Providing on-site guidance services.

>> INQUIRY

E-mail: hengtongblower@163.comTel: 0086-373-5467003(5467018)